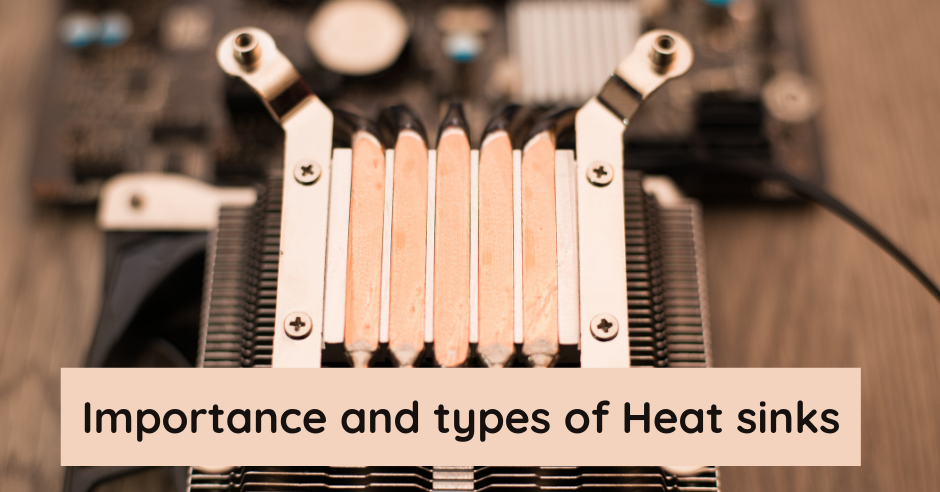

Importance and Types of Heat Sinks

Heat sink is an electronic segment or a gadget of an electronic circuit which scatters heat from different segments (basically from the force semiconductors) of a circuit into the encompassing medium and cools them for improving their exhibition, dependability and furthermore maintains a strategic distance from the untimely disappointment of the parts. For cooling purposes, it joins a fan or cooling gadget. Buying Heat sinks in refurbished markets helps you save money. Buy Refurbished Heat sinks at the best price in India by visiting an online marketplace.

Table of Content

Heat Sink Types

The Heat sinks are ordered into various classifications dependent on various standards. Allow us to think about the significant sorts, to be specific dynamic warmth sinks and uninvolved warmth sinks.

Dynamic Heat Sinks

These are by and large fan types and use power for cooling purposes. They can likewise be named as Heat sink or fans. The fans are additionally named metal ball type and sleeve bearing sort. The metal ball engine fans are liked as their working range is longer and they are less expensive with regards to long-range usage. The execution of these sorts of warmth sink is great, yet not for long-haul applications as they comprise moving parts and are somewhat costly also.

Inactive Heat Sinks

These don’t have any mechanical parts and are made of aluminum finned radiators. These disseminate nuclear power or warmth by utilizing the convection interaction. These are generally more dependable than the dynamic warmth sinks; and, for the proficient activity of detached warmth sinks, it is prescribed to keep up persistent wind current across their blades.

Aluminum Heat Sink

Warmth sinks are by and large made of metals; and, aluminum is the most widely recognized metal utilized in the heat sink. We know about the way that the warm conductivity of each metal is different. The warm conductivity of metal is relative to the warmth moved in the heat sink. In this manner, in the event that the warm conductivity of the metal expands, the warmth moving limit of the warmth sink will likewise increment.

Stepped Heat Sinks

These are made of metals that are stepped to frame a specific shape. This stamp makes the warmth sinks at whatever point metal is traveled through the stepping machine. These are less expensive contrasted with expelled heat sinks. These are utilized for low-power applications and subsequently, these are low in execution.

Machining Heat Sinks

These are produced by machining measure; as often as possible pack saw is utilized for eliminating a square of material to make entomb balances with exact dividing. These are costly as a ton of metal may go as wastage in the assembling cycle.

Fortified Fin Heat Sinks

These are much of the time utilized for truly huge applications that require reasonable execution like electric welding and DC-DC block applications. These are made by holding singular blades of metal to the base of a warmth sink. This should be possible in two strategies in particular warm epoxy which is conservative and the other is by brazing which is costly.

Collapsed Fin Heat Sinks

These collapsed balance heat sinks have a huge surface area and have collapsed heat sink material, and henceforth, they have superior and high warmth transition thickness. In these sinks, the air is coordinated to stream straightforwardly into heat sinks through some sort of channel. This makes the entire thing costly as the expense of assembling and ducting is remembered for the general expense of the sink.

Skived Heat Sinks

Skiving measure is utilized for assembling these sinks, which includes making fine squares of metals by and large copper. Henceforth, these are called skived heat sinks. These are medium to high-performing heat sinks.

Produced Heat Sinks

The metals like copper and aluminum are utilized to shape heat sinks by utilizing compressive powers. This cycle is named a manufacturing measure. Consequently, they are named as manufactured warmth sinks.

Single Fin Assembly Heat Sinks

These are lightweight and can be introduced in restricted spaces. They additionally have low to high performing capacity and can be utilized for some applications. However, a significant downside is that the region is a bit costly.

Swaged Heat Sinks

Swaging is a virus working manufacturing measure yet some of the time should be possible even as hot working interaction in which the components of a thing are adjusted into a kick the bucket. These are reasonable, medium performing, and are restricted in wind stream executives.

Significance of Heat Sinks in Electronic Circuits

A warmth sink is an inactive warmth exchanger, and it is intended to have an enormous surface zone in contact with the encompassing (cooling) medium like air. The segments or electronic parts or gadgets which are lacking to direct their temperature require heat sinks for cooling.

The focal preparing units and realistic processors of a PC are additionally cooled by utilizing the warmth sinks. Warmth sinks are additionally called Heat spreaders, which are every now and again utilized as covers on a PC’s memory to scatter its warmth.

In the event that warmth sinks are not accommodated in electronic circuits, then there will be an opportunity of disappointment of parts like semiconductors, voltage controllers, ICs, LEDs, and force semiconductors. Indeed, even while fastening an electronic circuit, it is prescribed to utilize a heat sink to stay away from over warming of the components.

Warmth sinks give heat dispersal, yet additionally utilized for nuclear power the board done by scattering heat when warmth is more. In the event of low temperatures, heat sinks are expected to give heat by delivering nuclear power for appropriate activity of the circuit.